Part II of the Graffiti Series: Are Anti-Graffiti Coatings Appropriate for Historic Masonry?

In this blog we will present findings for testing we performed to identify the appropriate anti-graffiti coating for a historic 1930’s building. This follows our previous Graffiti Response blog where we provided a series of quick dos and don’ts to help guide graffiti removal efforts for historic buildings.

The Problem:

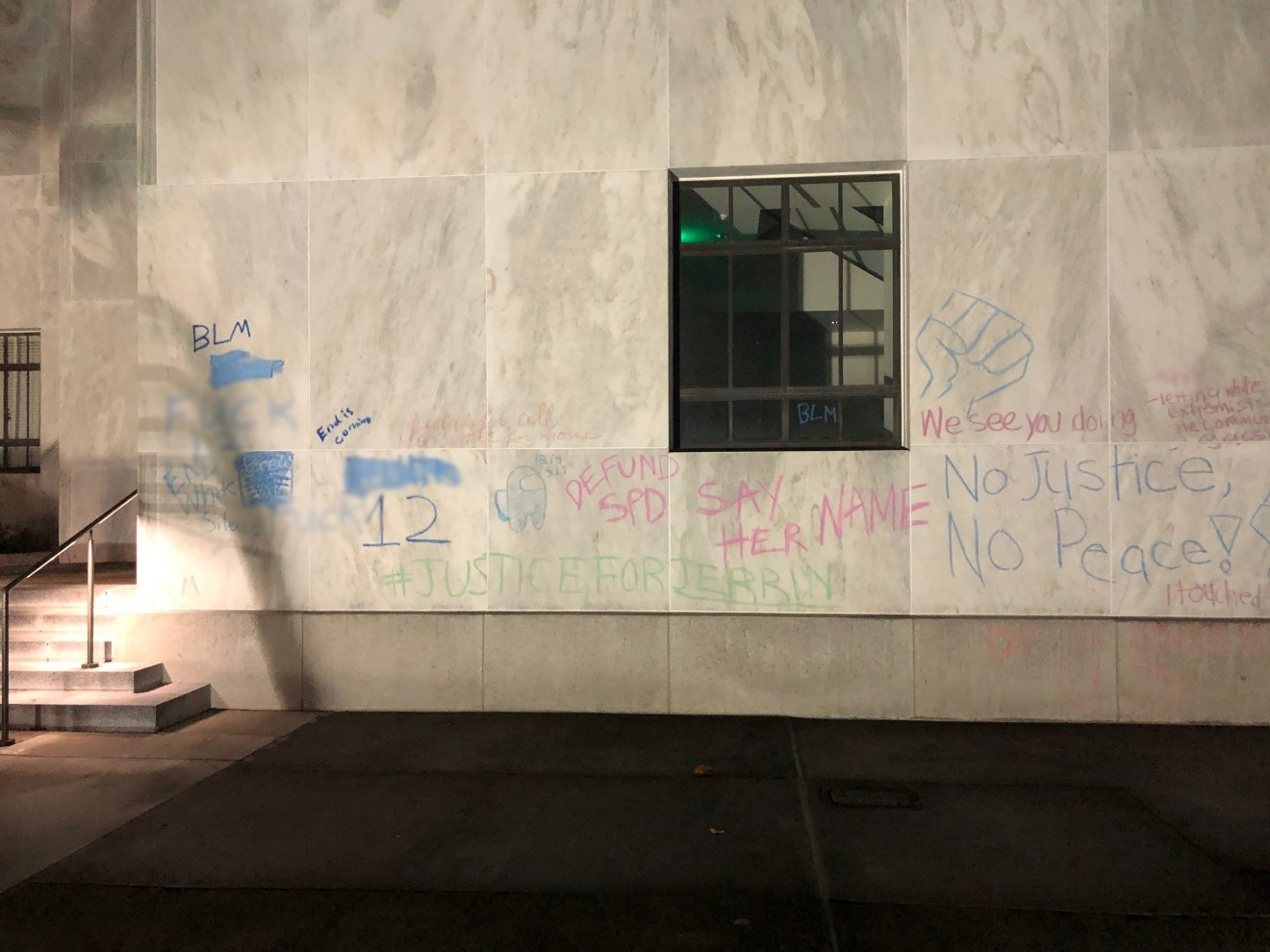

The Oregon State Capitol was subject to a series of tagging incidents during the 2020 social protests. These events comprised eight separate incidents. Each time professional masons were hired to carefully remove the graffiti, ensuring minimal damage to the underlying substrate. In one location, at the Friedlander Statue, a variety of cleaning methods and products were tested to remove a particularly offensive graphic, causing slight damage to the stone. In an effort to prevent this from happening again, ARG was asked to identify an appropriate anti-graffiti product for use at exterior stone at the Capitol. The overall goal was for future graffiti removal to be done more quickly and with less damage to the historic masonry should tagging incidents reoccur in the future. The areas of interest for the recommendation of an anti-graffiti coating were at easy to reach locations, including statues and the base of the building, all composed of Danby marble with limited areas of Cold Spring granite.

Background:

Anti-graffiti coatings are intended to act as a barrier to help prevent paint or marker from being absorbed into the porous substrate, and to make graffiti removal easier. The preservation industry in general is wary of applying clear coatings to historic masonry, which include both anti-graffiti coatings and water repellents. While there are similarities between these two types of coatings, the biggest difference is the underlying chemistry: most non-sacrificial graffiti control treatments can also be used for water repellency, but not all water repellents provide graffiti resistance. According to product literature, both are generally formulated to be vapor permeable, but the concern is that these types of coatings could in fact reduce vapor transmission occurring in the historic masonry assembly. This reduction in vapor transmission could trap moisture within the stone and lead to stone deterioration, including sugaring and spalling. Coatings may also alter the appearance of the stone, in both color and sheen. Damage from coatings on historic masonry is a well-documented condition and can be seen on many historic buildings in the Pacific Northwest.

ARG understands the risks of such applications but based on advancements in the field of masonry coatings feel that there are a variety of products available on the market that would pose minimal long-term damage to the masonry, assuming they are applied based on rigorous research and in-situ mock-ups to document efficacy, durability and impacts to masonry. Ideally testing would be accompanied by lab testing to confirm efficacy and vapor transmission of the products on the specific substrates they are being tested on. Challenges also exist for protection from graffiti on other materials. For example, bronze may be finished with wax, both for conservation of the metal as well as part of a maintenance cycle to act as a sacrificial coating for graffiti removal.

Types of Coatings on the Market:

There are generally two types of anti-graffiti coatings available in today’s market: non-sacrificial coatings, and sacrificial coatings. Non-sacrificial coatings, also referred to as permanent coatings, bond with the surface of the stone and are considered non-reversible until the coating wears off, which can take 10 to 15 years depending on the composition. There are various products available and depending on the manufacturer are chemically equivalent to Teflon, acrylic paint, silicone or polyester.

Sacrificial coatings, however, are temporary and are intended to be re-applied after tagging is removed. Depending on the manufacturer, they are chemically equivalent to starch, wax or carnuba wax. While the long-term effects of both types of coatings on historic masonry is not clear, in recent years the products have improved greatly. One issue that we ran into is that manufacturers do not maintain a database of case studies to monitor the long-term effects of anti-graffiti coatings or water-repellents on masonry buildings. In addition, changes in product chemistry make it difficult to compare and evaluate products over time. This is something that needs to be addressed by the industry.

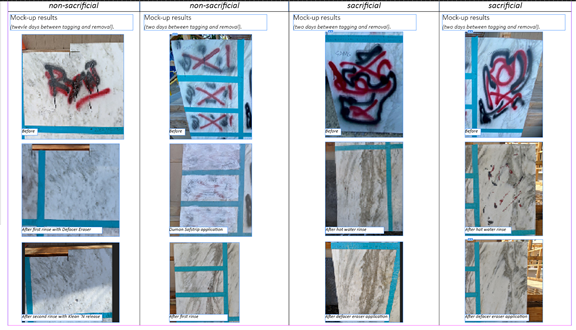

In order to determine which type of anti-graffiti coating is appropriate for application at the Oregon State Capitol, mock-ups were performed using existing marble and granite in storage. Temporary staging was set up on site while the mock-ups were performed and reviewed. A combination of black, red, and gold spray paint, as well as permanent black marker, was used to tag the stone samples. Effectiveness of graffiti removal was tested at intervals of 24 hours, and 12 days. The primary objective for these mock-ups was to observe how the products performed. Selection criteria included:

- The coating should be breathable.

- To monitor if any of the products changed the appearance from uncoated stone, such as creating a sheen or discoloration.

- Reversibility, to allow the coating to be completely removed.

- To test the anti-graffiti removal process to assess how effective the products were to protect the Danby marble and the Cold Spring granite.

One step that the testing did not include – because of cost – was lab testing for vapor transmission such as ASTM E96.

Findings:

In general, both the sacrificial and non-sacrificial coatings performed well as far as appearance and ease of graffiti removal. Listed below are the pros and cons of both types of products.

Two permanent coatings were tested (one solvent-based silicone elastomer and one aqueous silane system type):

Pros:

- Product is easy to apply with low-pressure spray, one coat usually sufficient

- Offers UV stability, vapor permeable

- Graffiti removal is fast using additional graffiti removing products

- Product does not need to be reapplied after each graffiti removal process.

- Product comes with 10-year warranty

Cons:

- Product is chemically harsher than those in sacrificial coatings

- Product is non-sacrificial, meaning it will remain on the stone for years after initial application

- Products required to remove the anti-graffiti coating can damage and darken the stone

- Commercial products are required to remove graffiti

- Can affect future patching, pointing and caulking

- The actual product cost was very expensive

Two sacrificial coatings were tested (one was “water-based” and the other was comprised of a polysaccharide solution and water):

Pros:

- Allows quick removal of graffiti stains with the use of warm pressurized water (Important! water has to be at least 180 degrees or it won’t effectively remove the graffiti)

- Will not alter the appearance of the stone

- Product is vapor permeable

- Reapplications of the coating can be reapplied by trained individuals (not just professional masons)

- Product is reversible and can be removed with hot water at any time

Cons:

- Product needs to be reapplied after each graffiti removal process

- Graffiti resistance may be reduced by maintenance cleaning

- Product needs to be completely removed and replaced every 5 years

- Commercial products may be required for graffiti removal if initial hot washes are not 100 percent effective

- Graffiti removal should be performed within 48 hours of tagging incident or else it will become increasingly difficult to remove the graffiti and may require use of strong chemical cleaners or paint strippers.

Recommendations: In the end we recommended a sacrificial coating be used for this effort. The main reasons for this are as follows:

- The sacrificial coating was successful in the mock-ups and did not appear to alter the stone appearance in any way (no yellowing, sheen, etc).

- We selected an anti-graffiti product from a manufacturer whose products we had used before with success for masonry cleaning and restoration on other parts of the building. The company has been reliable and available to be on site to answer questions and provide assistance, which is important for a project of this scope.

- The sacrificial coating can be removed with hot water at any time without damage to the stone, vs. permanent coatings that are designed to bond with the stone substrate and can only be removed with harsh chemicals.

- Historic review bodies would be more favorable to removable coatings.

- The product can be re-applied as required by trained staff. Permanent coatings can only be applied by trained masons.

- Sacrificial coatings are less expensive than permanent coatings; however, the cost of graffiti removal and reapplication should be factored into a building’s maintenance plan based on the history of tagging activity at the site

In the end, we went with a product that we felt would have the best appearance, the least chance of long-term damage to the masonry, and be the most reversible. That said, if case studies of permanent coatings on historic masonry were available that carefully monitored the effectiveness, breathability over time, and any long-term changes in appearance of the stone due to the product, we might have been able to argue for a permanent coating.

If anyone reading this blog is keeping track of these types of applications on historic masonry (anti-graffiti coatings and water-repellents), please let us know (m.foty@argcreate.com)! We plan to keep track of our own efforts in order to help inform our work, as well as that of the greater preservation industry.